Why Heat-Resistant Lubricants Are Essential in the Automotive Industry

Lubrication in a car or truck is not just about putting oil or grease somewhere parts move — it’s about matching the lubricant to the stress (mechanical load, pressure, speed, temperature, environment).

Post by: Sawiva | 2025-03-04 15:08:06

Why Heat-Resistant Lubricants Are Essential — With Top Brands & How to Use Them

Lubrication in a car or truck is not just about putting oil or grease somewhere parts move — it’s about matching the lubricant to the stress (mechanical load, pressure, speed, temperature, environment). When temperature gets high — from braking, turbocharging, exhaust, or heavy loads — ordinary lubricants can degrade, oxidize, thin out, lose film strength, cause friction, deposits, and failure. Heat-resistant lubricants are formulated to resist these problems. Below are some top brands, their strengths, and guidance on how to use them effectively.

Top Brands Known for Heat-Resistant/High-Temperature Automotive Lubricants

Here are some of the well-regarded brands globally and regionally, with specific product lines, and what they offer.

| Brand | Key Products / Lines Known for Heat Resistance | What Makes Them Good |

|---|---|---|

| Mobil (Mobil 1, Mobilgrease etc.) | Synthetic engine oils, high-temperature greases. Mobil synthetic oils maintain viscosity and oxidation stability under heat. | Very stable base stocks; good additive packages. Often used in OEM and performance applications. |

| Royal Purple | Synthetic motor oil, synthetic greases, gear oil etc. | Known for high performance; good for high stress, racing, turbocharged or supercharged engines. |

| Castrol | Castrol’s high temperature greases; Castrol Edge for engine protection under heat. | Wide product line; good availability. Their “Edge” oils are formulated for higher shear and temperature stability. |

| Shell Rotella | Heavy duty engine lubricants, gear oils, products rated for high-temp, high load conditions (especially in diesels / truck engines). | Designed for prolonged high temp, soot load, etc. Useful for commercial vehicles, fleet operation. |

| Omega (Fine Lubricant Solutions) | Greases like “Omega 33 Extreme Heat Resistant Grease”, “Omega 35 Hi-Temp MSL Grease” etc. | Offers products with very high temperature tolerances, synthetic or semi-synthetic bases, good for bearings etc. |

| Bechem / Berutox | From the BECHEM / Berutox line: “Berutox M21 KN”, “Ceritol PSA 12 H” etc. | Good for very hot bearing or exhaust adjacent parts; good corrosion protection; varied thickener systems. |

| Valvoline | Their high-quality greases, especially ones designed for high temperature or heavy duty use. | Often more available, good support; useful for more standard or mid-range applications. |

How to Use Heat-Resistant Lubricants: Best Practices

Knowing a high temp lubricant is good is only half the battle — using it correctly is just as important.

-

Match the Application to the Lubricant Rating

-

Use grease or oil whose temperature range (continuous and peak) covers what your component sees. E.g. brakes see very high peak temps; wheel bearings less so.

-

Use the proper additive or thickener type. For example, lithium complex, polyurea, calcium sulfonate, etc. Some are better for high temperature, others for water resistance or high load.

-

-

OEM and Manufacturer Specifications

Always check the vehicle’s manual or component-maker spec. They often require certain API ratings, viscosity grades, or grease thickeners. Using a lubricant that doesn’t meet those specs can void warranty or lead to failures. -

Proper Application Points and Methods

-

Grease fittings (zerk fittings): apply clean grease with the right tool, avoiding over-greasing, which can cause heat buildup.

-

Oil: ensure proper flow, filtration, oil change intervals are adhered to (high temp increases oxidation, so oil change intervals may need to be shorter).

-

Use anti-seize or ceramic greases in bolts/nuts that get hot (e.g. exhaust manifold bolts, turbo bolts) to avoid seizing when disassembling.

-

-

Monitor and Maintain

-

Periodically inspect for signs of lubricant failure: darkening, thickening, presence of sludge or varnish, rust, or metal particles in lubricant.

-

Check for leaks or grease wash-out (especially in wet or dusty environments), or grease being “pumped out” under vibration / motion.

-

Replace or re-lubricate as needed; high temp environments often require more frequent maintenance.

-

-

Environment & Operating Conditions

-

If operation includes exposure to moisture, dust, or chemical contaminants, choose greases / oils with corrosion inhibitors or good sealing properties.

-

For high load / high speed / shock / vibration, choose greases with extreme pressure (EP) or anti-wear (AW) additives.

-

In hotter climates, or under heavy load / long uphill drives etc., expect higher stress on lubricant.

-

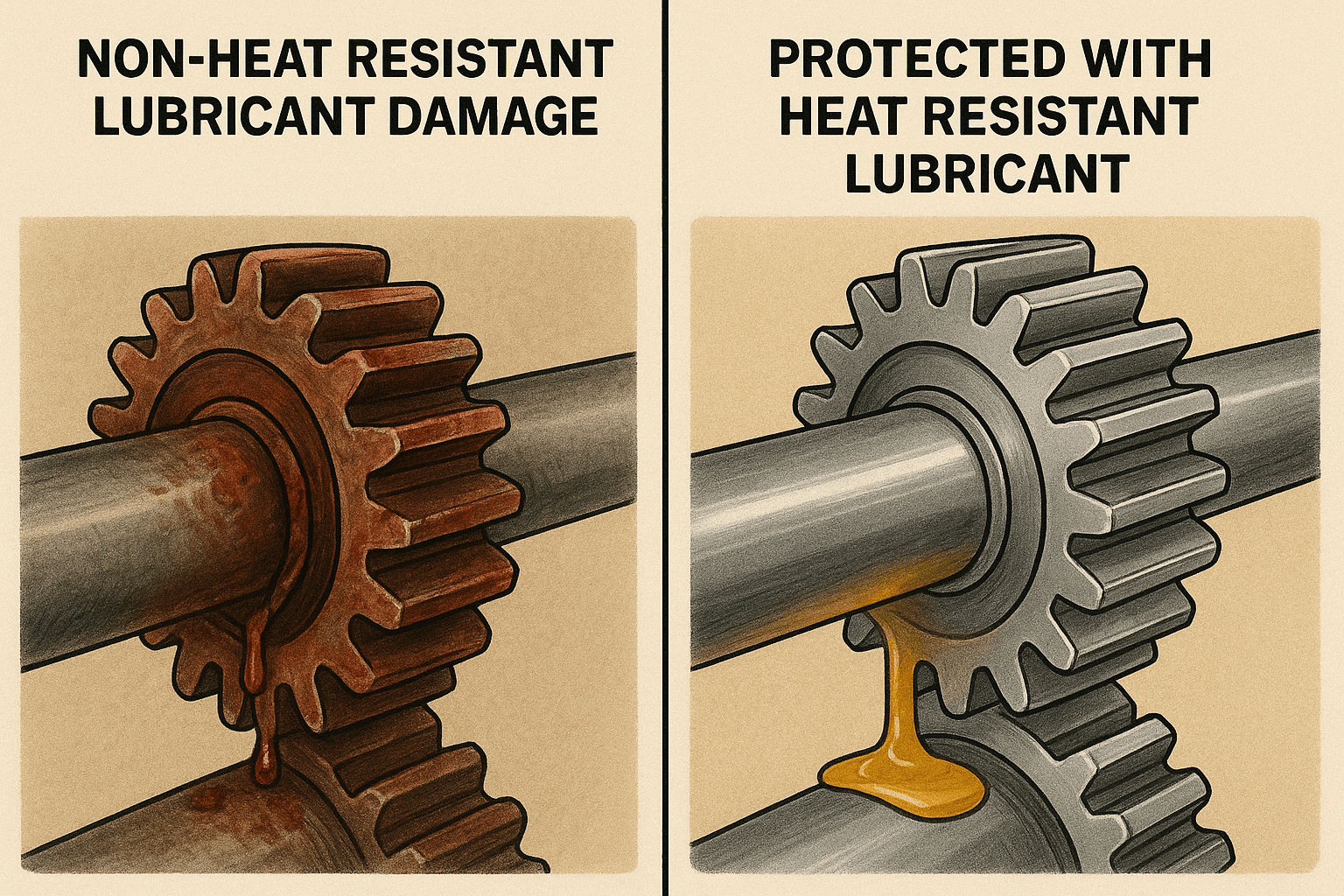

Dangers & Effects If You Use Non-Heat-Resistant Lubricants in High-Temp Zones

To reinforce the “why” part, here are what can go wrong:

-

Viscosity breakdown: Lubricants get thinner (lose viscosity) at high heat, so the protective film on moving surfaces becomes too thin → increased metal contact → wear → scoring / seizure.

-

Oxidation & sludge formation: Heat speeds up chemical reactions; oils oxidize, form acids, varnish, sludge; these deposit in oil galleries, filter, reduce flow, block passages (e.g. in turbo, hydraulic systems).

-

Additive depletion: Anti-wear/EP/corrosion inhibitors degrade faster; once they’re gone, the lubricant can’t protect.

-

Thermal softening / dropping point exceeded: Greases may melt, lose structure, liquefy and run off, leave parts dry.

-

Risk of component damage or failure: Bearings can overheat, warp; seals may fail; bolts seize; brakes may fade; engine parts may suffer from metal fatigue.

-

Safety risks: In worst cases, overheated parts can cause fires, or cause failures leading to accidents.

Practical Examples: Which Brand / Product for Which Use

To make this more concrete, here are some use-cases and suggestions of which types of product & brand might be good.

| Application | What You Need | Brand / Product Suggestion | Why It Works |

|---|---|---|---|

| Turbocharged / High-Performance Gas / Diesel Engines | High viscosity stability, oxidation resistance, low volatility | Mobil 1 synthetic oils; Royal Purple’s high performance motor oils | Helps maintain film under heat, resist sludge, handle boost & heat cycling. |

| Wheel Bearings (Heavy Duty, Trucks, Off-Road) | Grease with high dropping point, EP additives, water & wash-out resistance | Omega 33 Extreme Heat Resistant Grease; Berutox M21 KN; Castrol’s HT greases | They stay in place at high speeds/temperatures and resist wash-out in mud/rain. |

| Brake Components / Calipers / Pads / Disc Surfaces | Grease or anti-seize that withstands very high “spike” temps, resists corrosion | Permatex or similar ceramic / copper anti-seize / brake grease brands; brands like Omega or Castrol that have specific brake / caliper greases | Prevent squealing, sticking, caliper bolts seizing, easy removal for maintenance. |

| Exhaust Manifolds / Bolts / Flanges | Anti-seize compounds or high temp pastes; stick to metal surfaces, resist oxidation | High-temp copper or nickel anti-seize from brands like Permatex, or specialty greases that include nickel or copper solids | Prevents bolts from seizing due to heat cycles & corrosion; better service life. |

| Electric Motors / Alternators / Accessory Bearings (if subject to heat) | Greases with synthetic base + oxidation inhibitors + good mechanical stability | Omega line; Mobilgrease EP or similar synthetic greases | Keeps bearings quiet, reduces friction; synthetic bases handle heat better. |

Conclusion

Using heat-resistant lubricants isn’t just about “premium materials” — it’s about matching the real operating conditions. The right lubricant from a reputable brand, correctly applied and maintained, protects performance, reduces downtime, saves money in the long run, and improves safety. If you need recommendations tailored to your specific type of vehicle, climate, and driving style (or duty cycle), I’d be happy to help scope that out too.